Why Understanding Sprayer Parts is Essential for Efficient Application

Understanding Sprayer Parts is critical for achieving efficient application in agriculture. According to a report by the Agricultural Sprayers Association, outdated or improperly maintained sprayer components can lead to a 25% reduction in application efficiency. This highlights the necessity of knowing each part's function and importance. Experts stress that sprayer performance directly impacts crop yields and input costs.

John Smith, a renowned expert in spray technology, once stated, "Every component of a sprayer plays a pivotal role in delivering precision." This emphasizes the interconnectedness of sprayer parts, as one malfunctioning piece can compromise the entire system. Attention to detail is vital. Many farmers overlook regular maintenance, leading to significant losses in productivity.

Moreover, understanding sprayer parts fosters better decision-making when purchasing replacements or upgrades. Data shows that 40% of sprayer-related issues stem from incorrect parts selection. Reflection on this reveals a gap in knowledge that needs addressing. The cultivation of awareness around sprayer parts not only enhances efficiency but also promotes sustainability in agricultural practices.

The Importance of Sprayer Parts in Agricultural Efficiency

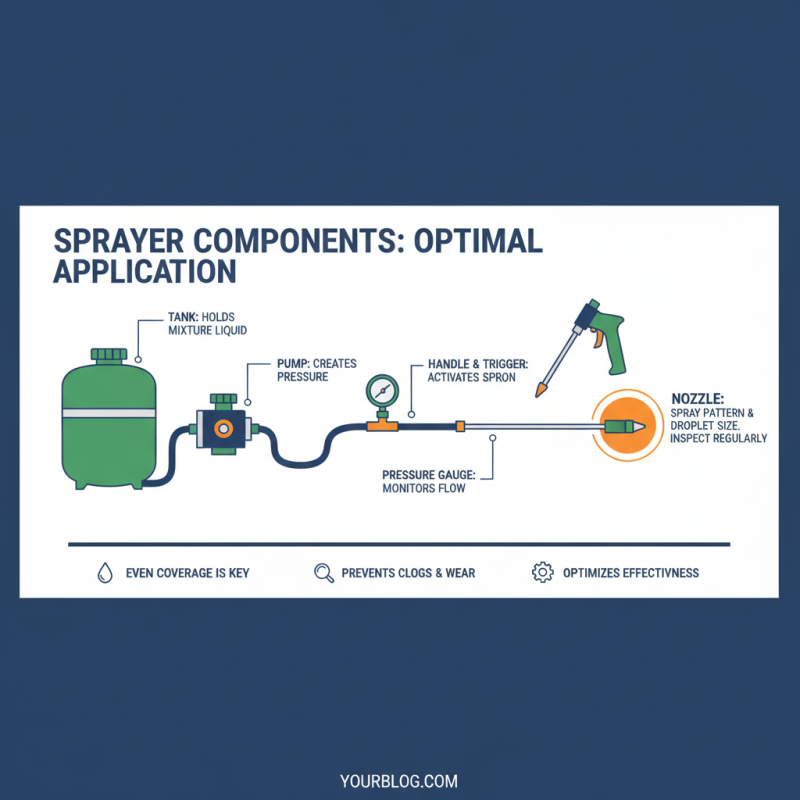

Understanding sprayer parts is crucial for achieving agricultural efficiency. Each component plays a vital role in the application process. A malfunctioning nozzle can lead to uneven distribution of chemicals. This inconsistency may result in crop damage or inadequate pest control. It's essential to know how every part works together for optimal performance.

Tips: Regularly inspect nozzles for wear and clogging. Replace them if needed. This simple action can save time and resources. Additionally, familiarize yourself with the pressure regulation system. It significantly influences the spray pattern and droplet size. Improper pressure can lead to excessive drift or runoff, impacting the environment.

Farmers often overlook smaller components like filters and hoses. These parts can degrade over time, affecting the sprayer’s overall functionality. Ignoring maintenance leads to bigger problems later. Always clean filters after each use to ensure efficient spraying. Proper care can prolong the lifespan of your sprayer. Each small action counts toward a more efficient application.

Key Components of Sprayers and Their Functions

Understanding the key components of sprayers is crucial for effective application. Each part plays a vital role in ensuring that the mixture is evenly distributed. Nozzles, for instance, determine the spray pattern and droplet size. A worn or clogged nozzle can cause uneven coverage. Regular inspection is necessary.

The pump is another essential component. It generates the pressure needed to push the liquid through the system. If the pump is faulty, the entire operation can be compromised. Always check for leaks or irregular noises. These signs indicate maintenance is needed.

Tips: Keep a spare set of nozzles handy. It’s cost-effective and saves time. Regularly clean the filters to prevent blockages. Take time to understand how each part interacts. Sometimes, it’s easy to overlook that one small piece can affect the entire performance. Reflect on your practices and make adjustments when necessary. Understanding these components empowers users for efficient application.

How Sprayer Parts Affect Application Accuracy

Understanding sprayer parts is crucial for achieving precise application. Every component plays a role in delivering the right amount of product. Nozzles, for instance, control droplet size and distribution. If a nozzle is clogged or damaged, it can lead to uneven application. The result? Some areas may receive too much, while others get too little. This directly impacts the efficiency of your spraying task.

Moreover, the pump and pressure settings significantly affect application accuracy. An improperly calibrated pump can create inconsistent spray patterns. This inconsistency can lead to waste and inefficiency. You might find yourself overworking certain areas while neglecting others. It’s essential to regularly inspect and maintain these parts. Small issues today can lead to bigger problems tomorrow.

Lastly, the importance of calibration cannot be overstated. Even if every part functions well, incorrect calibration skews results. You might think you've applied the right amount, but the evidence says otherwise. Regular checks can save time and resources. Understanding how each part interacts is vital for effective operation. One small part can lead to big changes in your results.

Maintenance Tips for Optimal Sprayer Performance

Regular maintenance of sprayer parts is crucial for ensuring performance. Inspecting hoses and nozzles often can prevent clogging. Over time, residue builds up, affecting the spray pattern. A simple visual check might reveal cracks or wear. Replace damaged parts promptly to avoid larger issues later on.

Cleaning the tank after every use is essential. Leftover chemicals can corrode the sprayer. A thorough rinse can save future headaches. Additionally, check the pressure gauge regularly. Inaccurate readings can lead to over or under-application. Sometimes, we forget these minor details, leading to mistakes.

Don’t neglect the pump. It requires lubrication as recommended in the manual. Make a habit of checking its function. If it struggles, there may be an underlying issue. Remember, every part plays a role in efficient application. Keep a maintenance log to track what needs attention. This can help identify patterns and prevent breakdowns. Ignoring these tasks can cost time and resources.

Efficiency of Sprayer Parts Maintenance

Troubleshooting Common Sprayer Issues for Better Efficiency

Understanding sprayer parts is vital for addressing common issues that affect efficiency. For instance, clogs in filters can lead to uneven application. According to industry studies, nearly 30% of sprayer problems result from poor maintenance. Regular checks can identify these issues before they escalate.

Another frequent concern is the nozzles. They can become worn or damaged, leading to inconsistent spray patterns. Research indicates that 15% of applications are compromised due to nozzle problems. Simple inspections can help spot these defects.

Upgrading to higher quality nozzles can also enhance performance, but many overlook this detail. Pump pressure plays a key role too. Incorrect settings can waste chemicals and time. Surprisingly, 25% of users report issues due to improper pressure. It's crucial to understand optimal settings for your specific tasks. Frequent adjustments and learning from past mistakes will contribute to better outcomes in the long run.

Related Posts

-

7 Best Gasoline Chain Saw Features That Will Revolutionize Your Cutting Experience

-

The Complete Handbook for Choosing the Perfect Hand Held Chain Saw

-

Exploring the Ultimate Guide to Choosing the Best Chain Saw for Your Needs

-

How to Choose the Best Chainsaw for Your Needs in 2025

-

How to Maintain Your Chain Saw for Optimal Performance

-

5 Compelling Reasons Why Chain Saws Are Essential for Efficient Tree Maintenance