Top 2025 Gasoline Engine Parts You Must Know for Optimal Performance

In the ever-evolving landscape of automotive technology, understanding the intricacies of gasoline engine parts is crucial for both enthusiasts and professionals seeking optimal performance. Renowned automotive expert Dr. John Smith emphasizes this point, stating, "The right gasoline engine parts can significantly enhance both efficiency and power, making knowledge about them essential for any serious technician." As advancements in engineering continue to push boundaries, grasping the essential components that contribute to engine performance becomes paramount.

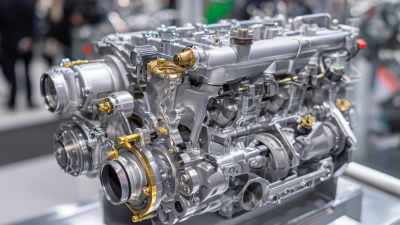

Gasoline engines, the lifeblood of countless vehicles, consist of multiple parts that work in harmony to deliver power, efficiency, and reliability. From the complex arrangement of the combustion chamber to the precision of fuel injectors, each part plays a pivotal role in the engine's functionality. In this article, we will delve into the top gasoline engine parts that you must know, unpacking their roles and significance in achieving peak performance.

Whether you're a seasoned mechanic or a passionate car owner, familiarizing yourself with these critical components will not only boost your understanding but also empower you to make informed decisions regarding maintenance and upgrades. Join us as we explore the essential gasoline engine parts that can make a remarkable difference in your vehicle's overall performance.

Essential Components of Gasoline Engines for Peak Performance

Gasoline engines are intricate machines that rely on several essential components to achieve optimal performance. One of the most critical parts is the fuel injection system, which plays a vital role in delivering the correct amount of fuel to the combustion chamber. This system ensures that the fuel is atomized properly for efficient combustion, enhancing power output and minimizing emissions. An efficient fuel injection system can significantly improve engine responsiveness and fuel economy, making it a focal point for any performance-oriented gasoline engine.

Another crucial component is the ignition system, which ignites the air-fuel mixture in the combustion chamber. A high-performance ignition system, consisting of spark plugs, ignition coils, and wiring, can greatly influence engine efficiency and starting ability. Consistent and strong spark delivery is essential to ensure smooth engine operation and optimal power generation. Furthermore, the cooling system, which maintains the engine at an ideal operating temperature, is vital for preventing overheating that can lead to severe damage. The combination of these components—fuel injection, ignition, and cooling systems—forms the backbone of a gasoline engine’s performance, making their maintenance and optimization essential for achieving peak efficiency.

Understanding Engine Block Design and Its Impact on Functionality

The design of the engine block is a critical factor in determining the overall performance and efficiency of a gasoline engine. Engine blocks serve as the core structure housing various components, including cylinders, crankshaft, and pistons. Their configuration directly influences the engine's ability to generate power, manage heat, and ensure durability. For instance, a well-engineered engine block design can optimize airflow and combustion efficiency, leading to enhanced power output and reduced emissions. Moreover, the material used in the block, whether cast iron or aluminum, plays a role in weight distribution and thermal conductivity, further impacting engine performance.

The cooling system's integration with the engine block is another significant aspect that affects functionality. An effective cooling system ensures that the engine operates within an optimal temperature range, preventing overheating and potential damage. Furthermore, the arrangement of coolant passages within the engine block can facilitate better heat dissipation, promoting a more stable operating condition. In modern designs, advancements such as integrated water jackets and improved sealing techniques have been introduced to enhance thermal management, thereby supporting the engine in maintaining consistent performance during varying operating conditions.

Top 2025 Gasoline Engine Parts You Must Know for Optimal Performance

| Part Name | Material | Functionality | Impact on Performance | Maintenance Tips |

|---|---|---|---|---|

| Engine Block | Cast Iron / Aluminum | Houses engine components and creates compression | Affects durability and thermal efficiency | Regular inspections for cracks and deformations |

| Pistons | Aluminum Alloy | Converts combustion energy into mechanical work | Efficiency and power output increase with proper fit | Monitor for wear and replace if necessary |

| Crankshaft | Forged Steel | Converts linear motion from the pistons into rotational motion | Crucial for engine balance and efficiency | Check for alignment and bearings condition |

| Cylinder Head | Aluminum / Cast Iron | Houses intake and exhaust valves; facilitates combustion | Influences airflow and power generation | Inspect for warping and maintain valve seals |

| Fuel Injectors | Plastic / Metal | Deliver fuel to the combustion chamber | Core to optimal fuel mixture and efficiency | Clean regularly to prevent clogging |

The Role of Pistons and Piston Rings in Engine Efficiency

Pistons and piston rings are critical components in gasoline engines that significantly contribute to engine efficiency and performance. The piston transfers the force generated during combustion to the crankshaft, transforming the linear motion into rotational energy. According to the Society of Automotive Engineers (SAE), the efficiency of a gasoline engine can be affected by the design and material of the pistons, which must endure extreme temperatures and pressures. Advancements in piston technology have led to the use of lightweight materials such as forged aluminum alloys, which can reduce overall engine weight and improve responsiveness and fuel efficiency.

Piston rings, meanwhile, play an essential role in sealing the combustion chamber, controlling oil consumption, and managing heat transfer from the piston to the cylinder wall. A recent study from the International Journal of Engine Research highlighted that optimized piston ring designs can reduce friction losses by up to 30%, a significant improvement that directly impacts fuel economy and emissions. Proper maintenance and periodic replacement of these components can ensure that engines operate at peak efficiency, ultimately leading to a reduction in greenhouse gas emissions and improved overall performance.

Importance of Fuel Injectors in Combustion and Power Output

Fuel injectors play a crucial role in the performance of gasoline engines, significantly impacting combustion efficiency and overall power output. These components are responsible for delivering the precise amount of fuel into the combustion chamber at the right time, which is essential for optimizing air-fuel mixtures. According to a report from the Society of Automotive Engineers (SAE), an engine's performance can improve by up to 30% with the use of advanced fuel injection technologies, highlighting their importance in modern vehicle design.

In a gasoline engine, the efficiency of combustion directly influences power output and emissions. Studies indicate that well-maintained and properly functioning fuel injectors can reduce unburned fuel emissions by 40%, contributing not only to better performance but also to environmental sustainability. Furthermore, the variability in spray patterns produced by fuel injectors affects the atomization of fuel, which in turn affects the combustion process. Research has shown that optimizing the injector design can lead to a more homogeneous air-fuel mixture, enhancing torque and horsepower, ultimately leading to a better driving experience. Thus, understanding the mechanics of fuel injectors is essential for anyone aiming to boost engine performance effectively.

Maintaining Optimal Performance with Quality Ignition Systems

A reliable ignition system is a crucial component for maintaining the optimal performance of gasoline engines. It is responsible for igniting the air-fuel mixture within the engine's cylinders, ensuring efficient combustion. Quality ignition systems utilize advanced technologies that enhance spark delivery and timing, which directly influences fuel efficiency and engine power. By ensuring a strong, consistent spark, these systems help to minimize misfires and reduce emissions, ultimately leading to better overall engine health.

Regular maintenance and timely replacement of ignition components, such as spark plugs, ignition coils, and distributors, are essential for sustaining performance. Worn or faulty parts can cause a range of issues, including reduced acceleration, increased fuel consumption, and rough idling. Conducting routine checks and adhering to manufacturer recommendations helps vehicle owners prevent these problems and maintain optimal engine performance.

Prioritizing a high-quality ignition system not only boosts the engine’s output but also extends its lifespan, providing drivers with a reliable and efficient driving experience.

Related Posts

-

Innovative Gasoline Engine Parts Showcased at the 138th China Import and Export Fair in 2025

-

Top 5 China Chain Saws to Buy in 2025: Ultimate Guide for Outdoor Enthusiasts

-

Solutions for Maximizing Efficiency with Gasoline Chain Saws in the Forestry Industry

-

7 Essential Tips to Maximize the Performance of Your 40.2cc Gasoline Chain Saw

-

10 Essential Chainsaw Parts You Need for Optimal Performance

-

The Future of Outdoor Power Tools with Ms880 Chainsaw Innovation