2025 Top 5 Gasoline Engine Parts You Can't Afford to Miss

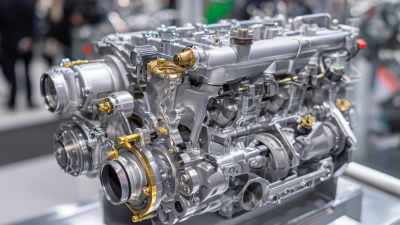

In the rapidly evolving automotive industry, keeping up with the latest advancements in gasoline engine technology is crucial for both enthusiasts and professionals alike. As we approach 2025, understanding the essential components of gasoline engines becomes increasingly important for optimizing performance, efficiency, and longevity. This article explores the top five gasoline engine parts that are set to transform the market, ensuring that you stay informed about the innovations driving this vital sector.

From cutting-edge fuel injectors to advanced ignition systems, these components not only enhance performance but also contribute to more environmentally friendly driving experiences.

We will delve into the features and benefits of each part, offering insights on why they cannot be overlooked in the coming years. Whether you are a mechanic looking to upgrade your toolkit or a car owner eager to enhance your vehicle's capabilities, familiarizing yourself with these gasoline engine parts will empower you to make informed decisions and keep pace with the future of automotive technology.

Key Innovations in Fuel Injection Systems: Enhancing Engine Efficiency by 25%

The evolution of fuel injection systems is critical for enhancing engine efficiency, and the innovations anticipated in 2025 are set to revolutionize gasoline engines. With the integration of advanced technologies, these cutting-edge systems can improve fuel delivery precision, ensuring optimal combustion and significantly reducing fuel consumption by up to 25%. This leap in efficiency not only addresses environmental concerns but also provides tangible savings for drivers, making fuel injection upgrades a must-consider for modern vehicles.

Tip: When looking to improve your vehicle's performance, consider upgrading to the latest fuel injection system available. Research and choose a system that complements your engine type and driving habits, as this will maximize efficiency gains and help you save on fuel costs.

Additionally, innovation in sensor technology allows real-time monitoring of combustion parameters, enabling automatic adjustments to fuel mixture and timing. Such advanced systems enhance responsiveness and adaptability, which is critical for meeting the demands of diverse driving conditions. By enhancing these systems, manufacturers are not only increasing engine power but also contributing to a cleaner, more sustainable automotive future.

Tip: Regular maintenance of your fuel injection system can help maintain its efficiency. Clean the injectors periodically and always use high-quality fuel to prevent carbon buildup, ensuring your engine runs smoothly while reaping the benefits of these innovative technologies.

The Impact of Turbochargers on Power Output and Fuel Economy in Modern Engines

Turbochargers have revolutionized modern gasoline engines by significantly enhancing their power output and fuel efficiency. By utilizing exhaust gases to spin a turbine, turbochargers compress incoming air, allowing for more fuel to burn during combustion. This results in increased horsepower without requiring a larger engine displacement. Consequently, manufacturers can produce smaller, lighter engines that deliver the performance traditionally associated with larger counterparts, striking an ideal balance between power and efficiency.

In addition to boosting performance, turbochargers contribute to improved fuel economy. The ability to extract more energy from each drop of fuel means that drivers can achieve greater mileage without sacrificing speed or acceleration. With rising fuel costs and environmental awareness, the implementation of turbocharger technology has become essential for automakers looking to meet stricter emissions regulations while appealing to consumers seeking value. As we approach 2025, the integration of advanced turbocharging systems will continue to be a crucial component in the evolution of gasoline engines, merging performance with sustainability in the automotive industry.

Impact of Turbochargers on Power Output and Fuel Economy in Modern Engines

Understanding the Role of Exhaust Systems in Emission Control and Performance

The exhaust system plays a crucial role in controlling emissions and enhancing the performance of gasoline engines. By channeling the exhaust gases away from the engine and reducing harmful pollutants, it ensures compliance with environmental regulations and improves air quality. High-performance exhaust systems often utilize advanced materials and designs to not only minimize back pressure but also optimize the flow of exhaust gases, leading to improved engine efficiency and power output.

In addition to emission control, an effective exhaust system can significantly affect the overall performance of the vehicle. It can help in tuning the engine's sound, allowing enthusiasts to enjoy a more thrilling auditory experience while driving. Moreover, modern exhaust systems are designed with components such as catalytic converters and mufflers that contribute to quieter operation and reduced vibration. Investing in high-quality exhaust components is essential for those looking to enhance their vehicle's performance and longevity, making them a must-have in any gasoline engine maintenance strategy.

Advanced Engine Control Modules: Revolutionizing Performance with Real-Time Analytics

Advanced Engine Control Modules (ECMs) are at the forefront of transforming automotive performance through real-time analytics. In 2022, the global demand for ECMs increased significantly, driven by the exponential rise in vehicle electrification and the shift towards more efficient internal combustion engines. According to a report by MarketsandMarkets, the engine control unit (ECU) market is projected to reach $73.6 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.8%. This growth is fueled by the integration of advanced analytics that enhance engine performance while optimizing fuel efficiency.

These ECMs leverage real-time data to monitor engine performance metrics, such as air-fuel ratios and ignition timing. By utilizing advanced algorithms, they can make instantaneous adjustments to optimize combustion and reduce emissions. A study conducted by the International Energy Agency revealed that vehicles equipped with sophisticated ECMs can reduce fuel consumption by up to 15% compared to traditional models. As manufacturers continue to adopt more intelligent systems, the advancements in ECM technology are set to play a pivotal role in shaping the future of automotive engineering.

Trends in Valve Train Technology: Improving Durability and Reducing Maintenance Costs

The advancements in valve train technology have become crucial for enhancing the performance and longevity of gasoline engines. Recent studies indicate that improving durability through innovative materials and designs can significantly reduce maintenance costs. For instance, the use of high-strength steel alloys and composite materials in the manufacturing of valve springs is predicted to increase the lifespan of these components by up to 30%, thereby lowering the frequency of replacements and associated labor costs. According to a report from the Automotive Research Institute, maintenance costs associated with valve train issues account for approximately 15% of total engine service expenses, which emphasizes the need for advancements in this area.

Moreover, the integration of variable valve timing (VVT) systems has revolutionized fuel efficiency and emissions control. Data from the International Council on Clean Transportation suggests that engines equipped with VVT can achieve up to 10% better fuel efficiency compared to traditional setups. This is particularly critical given the increasing pressure on automakers to meet stringent emissions standards. By investing in the latest valve train technologies, manufacturers can not only ensure compliance with regulations but also enhance consumer satisfaction with more reliable and efficient vehicles. The ongoing trends indicate that focusing on these innovative technologies will be a key element in the evolution of gasoline engine performance.

2025 Top 5 Gasoline Engine Parts You Can't Afford to Miss - Trends in Valve Train Technology: Improving Durability and Reducing Maintenance Costs

| Part Name | Material | Durability (Years) | Maintenance Frequency (Miles) | Cost ($) |

|---|---|---|---|---|

| Camshaft | Alloy Steel | 12 | 60,000 | 450 |

| Valves | Titanium | 15 | 80,000 | 300 |

| Springs | High Carbon Steel | 10 | 50,000 | 150 |

| Lifters | Composite Material | 8 | 40,000 | 200 |

| Timing Belt | Aramid Fiber | 6 | 100,000 | 75 |

Related Posts

-

How to Choose the Right Gasoline Engine Parts for Your Project

-

Innovative Gasoline Engine Parts Showcased at the 138th China Import and Export Fair in 2025

-

How to Master Your Ms880 Chainsaw for Ultimate Performance

-

7 Best Gasoline Chain Saw Features That Will Revolutionize Your Cutting Experience

-

How to Maintain Your Chain Saw for Optimal Performance

-

Exploring the Ultimate Guide to Choosing the Best Chain Saw for Your Needs