2025 How to Identify and Replace Essential Gasoline Engine Parts Effectively

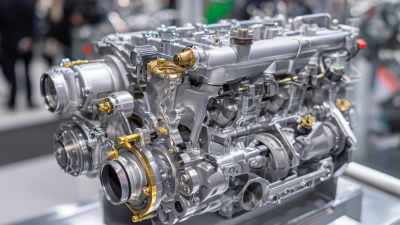

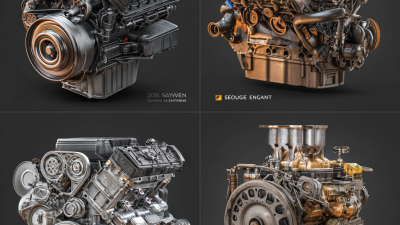

Identifying and replacing essential gasoline engine parts is a crucial skill for any vehicle owner or mechanic, especially as we look towards the advancements of 2025 and beyond. With the increasing complexity of gasoline engines, understanding the function and importance of each component becomes paramount. Whether you are dealing with routine maintenance or addressing significant repairs, knowledge about gasoline engine parts empowers you to make informed decisions and ensures optimal performance of your vehicle.

In this evolving landscape of automotive technology, effectively identifying which parts need replacement can save both time and money. Utilizing proper diagnostic tools and approaches will enable you to conduct thorough inspections and pinpoint issues before they escalate. Moreover, familiarity with the various gasoline engine parts, from spark plugs to fuel injectors, is essential in ensuring that any replacement process is executed correctly. By following systematic guidelines, you can enhance not only the longevity of your engine but also improve your overall driving experience. This article will guide you through the essential steps to master the identification and replacement of gasoline engine parts effectively, while equipping you with valuable insights for 2025 and beyond.

Identifying Essential Gasoline Engine Parts: A Comprehensive Guide

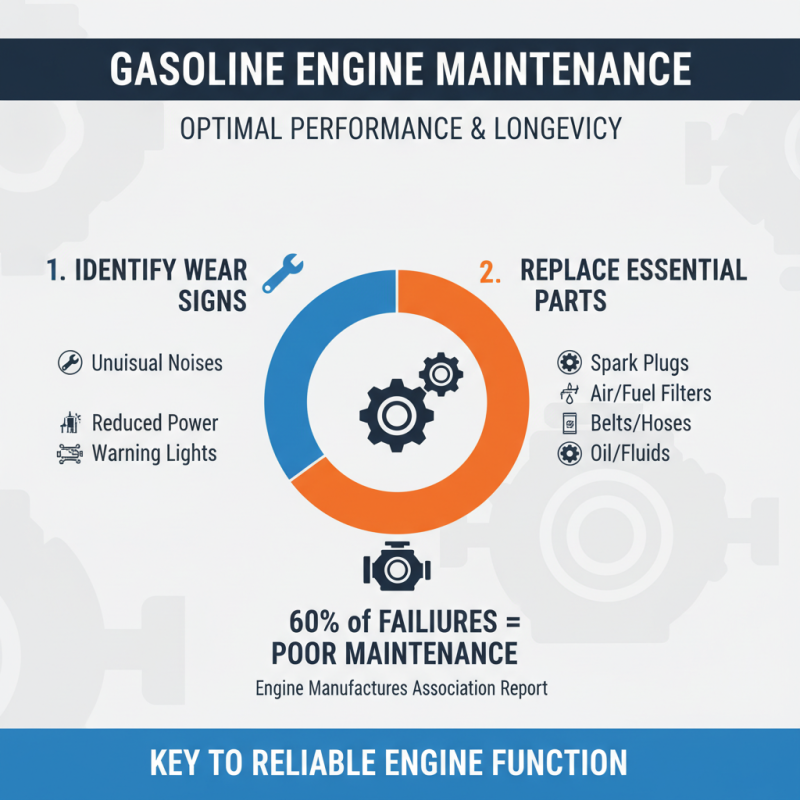

Understanding the essential components of gasoline engines is crucial for both enthusiasts and professionals in the automotive industry. A comprehensive guide on identifying these parts reveals that there are several key components that consistently require attention. According to a report from the Society of Automotive Engineers, around 60% of all engine failures are attributed to issues related to the fuel delivery system, including fuel injectors and pumps. Regular inspection can help prevent significant malfunctions and extend the engine's lifespan.

When identifying these essential parts, one must also consider components such as the ignition system, which is fundamental for engine performance. Research indicates that approximately 30% of vehicle owners neglect this area, resulting in decreased fuel efficiency and increased emissions. Regular maintenance and timely replacement of spark plugs and ignition coils are recommended by the Automotive Service Association to ensure optimal operation. Understanding these parts not only aids in effective troubleshooting but also enhances the engine's overall performance and reliability.

Essential Gasoline Engine Parts Identification and Replacement Needs (2025)

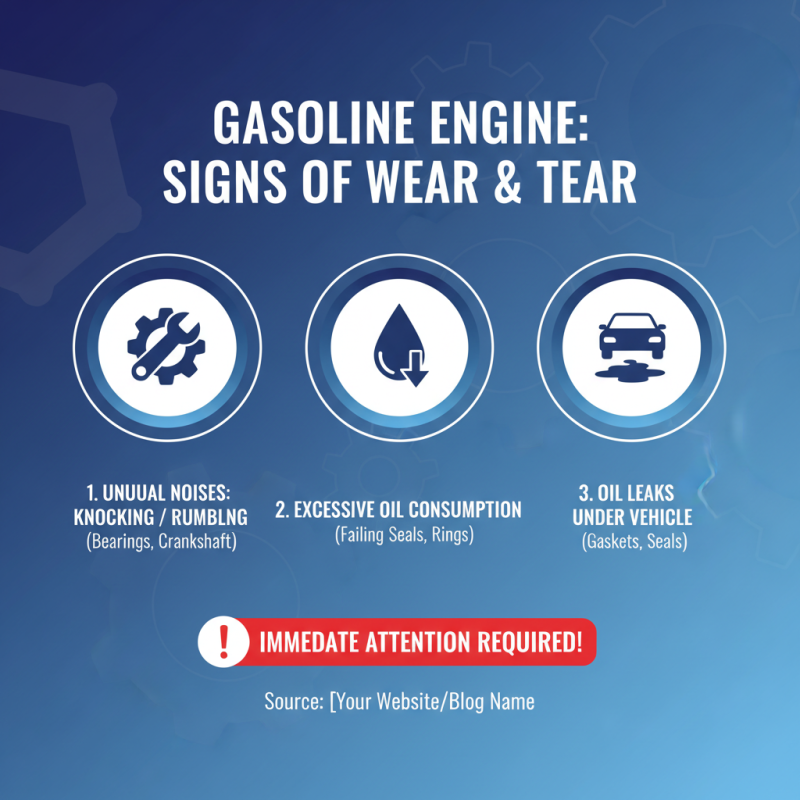

Common Signs of Wear and Tear in Gasoline Engine Components

When it comes to maintaining your gasoline engine, being vigilant about the signs of wear and tear in its components is crucial. Common indicators include unusual noises such as knocking or rumbling, which may suggest issues with the engine's internal parts such as bearings or the crankshaft. Additionally, excessive oil consumption or leaks under the vehicle can signal a failing oil seal or other critical components that require immediate attention.

Another clear sign of wear is a decrease in engine performance, noticeable through reduced acceleration or irregular idling. These symptoms often point to problems with the fuel system or ignition components. A visual inspection can also reveal cracks, rust, or damage to various engine parts, such as the hoses and belts, indicating that they may need replacement.

Tips to keep your engine running smoothly include regularly checking fluid levels and topping them off as necessary, as well as scheduling routine inspections with a qualified mechanic. It's also beneficial to keep an eye on the mileage and adhere to service recommendations for major components like the timing belt or water pump, ensuring that minor issues don't escalate into costly repairs. Regular maintenance is key to extending the life of your gasoline engine and avoiding breakdowns.

Step-by-Step Procedures for Replacing Key Engine Parts

When it comes to maintaining a gasoline engine, identifying and effectively replacing essential parts is crucial for optimal performance and longevity. According to a report from the Engine Manufacturers Association, approximately 60% of engine failures can be traced back to improper maintenance or overlooked component replacement. This underscores the importance of recognizing the signs of wear and knowing how to replace parts effectively.

To begin the replacement process, one should start by diagnosing the engine's performance issues. Common indicators such as unusual noises, decreased power, or excessive exhaust emissions can provide valuable clues. For example, a change in engine noise often points to issues with the exhaust system or worn-out engine mounts. The next step involves securing the right parts and tools, which can enhance the efficiency and quality of the replacement process. Industry professionals recommend using OEM (Original Equipment Manufacturer) parts, as they ensure compatibility and reliability that after-market parts may not guarantee.

Once the components are identified, the replacement should follow a step-by-step procedure. For instance, when replacing a timing belt, it’s essential to consult the vehicle’s service manual for specific torque specifications and tensioning procedures. Regular check-ups and methodical replacement can lead to a significant reduction in engine issues, as noted by a study from the Society of Automotive Engineers, which found that a well-maintained engine can improve fuel efficiency by up to 25%. Following these guidelines will not only streamline the process but also extend the life of your gasoline engine.

Tools and Equipment Needed for Effective Engine Part Replacement

When it comes to replacing essential gasoline engine parts, having the right tools and equipment is critical for achieving effective repairs and ensuring optimal engine performance. According to a 2023 industry report from the Automotive Service Association, approximately 70% of DIY mechanics cite the lack of appropriate tools as a significant barrier to successful engine maintenance. Thus, investing in quality equipment can significantly enhance both the ease and quality of your repair work.

Essential tools for effective engine part replacement include a comprehensive socket set, torque wrenches, and adjustable pliers. A sturdy floor jack and jack stands are vital for safely lifting the vehicle, allowing for easy access to parts beneath. Additionally, an engine hoist may be necessary for heavier components, especially in larger vehicles. Don’t overlook smaller tools such as screwdrivers, wire cutters, and a comprehensive set of picks and scrapers, as these can help in precision repairs and detailed work.

**Tip:** Always ensure your workspace is well-organized and well-lit, as a clutter-free environment can drastically reduce the risk of losing small components or making critical errors during the replacement process. Furthermore, having a reliable repair manual or access to quality online resources can aid in ensuring that you are using the correct techniques for your specific engine model. As the industry evolves, being equipped with the right tools not only simplifies the replacement process but also enhances the overall efficiency and effectiveness of your mechanical repairs.

Maintenance Tips for Prolonging the Life of Gasoline Engine Parts

To prolong the life of gasoline engine parts, regular maintenance is crucial. One of the most effective ways to ensure longevity is through routine inspections. Checking engine oil levels and quality is essential; clean oil reduces friction and wear. Additionally, replacing oil filters at suggested intervals helps keep the engine running smoothly by preventing contaminants from circulating. Regularly inspecting air filters is also vital, as a clean air filter allows for optimal airflow, improving fuel efficiency and engine performance.

Another important maintenance tip is to pay attention to the cooling system. Keeping the radiator and coolant in good condition prevents overheating, which can cause severe damage to engine components. Flushing the cooling system periodically and replacing the coolant can help maintain an efficient operating temperature. Furthermore, belts and hoses should be inspected for wear and replaced as necessary. Addressing small issues before they escalate into significant problems not only extends the life of the engine parts but also enhances overall reliability and performance.

2025 How to Identify and Replace Essential Gasoline Engine Parts Effectively - Maintenance Tips for Prolonging the Life of Gasoline Engine Parts

| Part | Signs of Wear | Replacement Frequency (Miles) | Maintenance Tips |

|---|---|---|---|

| Spark Plugs | Poor engine performance, misfires | 30,000 - 100,000 | Regularly inspect and replace as needed |

| Air Filter | Reduced fuel efficiency, engine stalling | 15,000 - 30,000 | Check every oil change and replace if dirty |

| Fuel Filter | Engine misfires, poor acceleration | 30,000 - 50,000 | Replace with every fuel system service |

| Oil Filter | Dirty oil, decreased engine efficiency | 5,000 - 7,500 | Change with every oil change |

| Timing Belt | Engine noise, poor combustion | 60,000 - 100,000 | Inspect periodically and replace as per service manual |

Related Posts

-

Top 10 Gasoline Engine Parts That Maximize Performance and Enhance Longevity

-

How to Choose the Right Gasoline Engine Parts for Your Project

-

Innovative Gasoline Engine Parts Showcased at the 138th China Import and Export Fair in 2025

-

2025 Top Gasoline Engine Parts You Need to Know for Optimal Performance

-

2025 Top 5 Gasoline Engine Parts You Can't Afford to Miss

-

The Ultimate Guide to Choosing the Best 40.2cc Chain Saw for Your Needs