10 Essential Chainsaw Parts You Need for Optimal Performance

A chainsaw is more than just a versatile tool for cutting wood; it is a combination of various essential components that work together to deliver optimal performance. Understanding the crucial chainsaw parts and their functions not only enhances your ability to maintain and operate your tool effectively but also ensures safety during use. Whether you are a seasoned professional or a weekend warrior tackling DIY projects, recognizing the significance of each part is vital for achieving the best results.

In this article, we will explore ten essential chainsaw parts that are fundamental to maximizing your chainsaw's efficiency and longevity. From the sharpness of the chain to the power of the engine, each component plays a critical role in the overall functionality of your chainsaw. By gaining insights into these parts, users can make informed decisions about maintenance, troubleshooting, and upgrades, ultimately leading to a more enjoyable and productive chainsaw experience.

Understanding the Importance of Chainsaw Components for Performance

Understanding the importance of chainsaw components is crucial for achieving optimal performance in any cutting task. Each part of a chainsaw plays a specific role, and their effective collaboration ensures the tool operates efficiently. For instance, the engine powers the entire system, while the bar and chain are responsible for the actual cutting. A lack of proper maintenance or the use of subpar parts can lead to decreased performance, increased wear, and even potential safety hazards.

In addition to the engine and cutting components, other parts such as the air filter, spark plug, and fuel system are essential for maintaining the chainsaw's operational efficiency. The air filter prevents dirt and debris from entering the engine, while the spark plug ignites the fuel-air mixture necessary for combustion. Regular inspection and timely replacement of these components can significantly enhance the chainsaw's reliability and longevity. Understanding these various elements fosters better maintenance practices, ensuring that the chainsaw remains a trusted tool for any job.

Key Components: Essential Chainsaw Parts for Smooth Operation

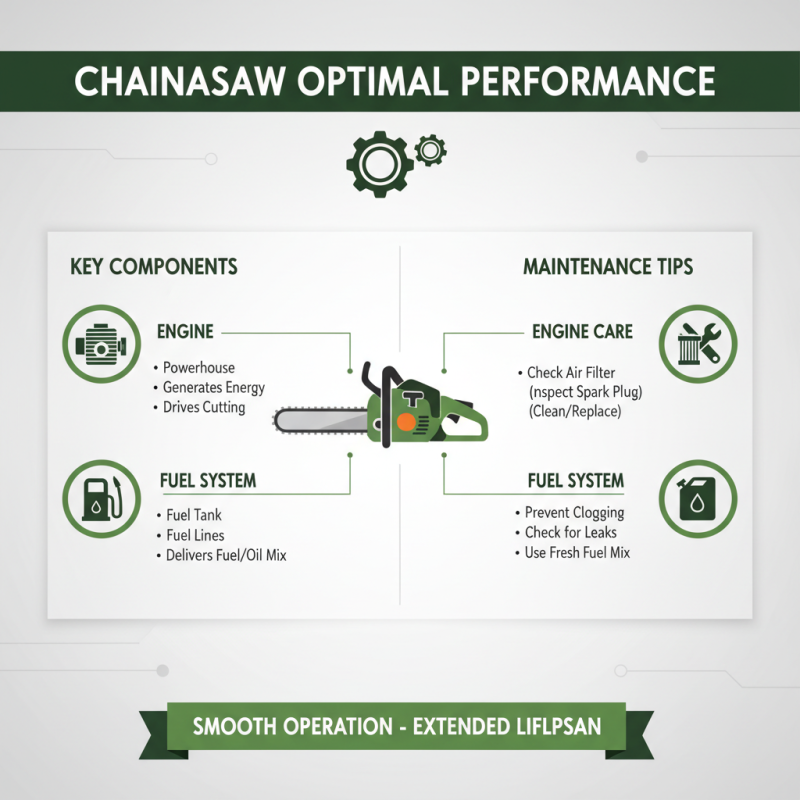

When it comes to ensuring a chainsaw operates smoothly, understanding its key components is crucial. The engine is the powerhouse of the chainsaw, providing the necessary energy for cutting through wood. Regular maintenance of the engine, including checking air filters and spark plugs, can significantly enhance performance. Additionally, the fuel system, which includes the fuel tank and fuel lines, is vital for delivering the right mix of gasoline and oil. Any clogging or leakage in these parts can lead to inefficient performance and potential damage.

Another essential part is the cutting mechanism itself, consisting of the bar and chain. The chainsaw bar provides the guide for the chain's movement, while the chain is responsible for cutting through materials efficiently. Frequent sharpening of the chain and proper lubrication of the bar not only improve cutting efficiency but also extend the lifespan of these components. Furthermore, safety features like the chain brake and throttle trigger ensure the user's protection while enhancing control during operation. Regularly inspecting and maintaining these key components helps achieve optimal performance and prolongs the overall life of the chainsaw.

How the Chainsaw Engine Affects Cutting Efficiency

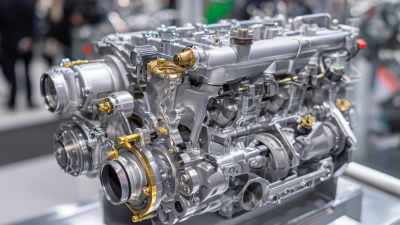

The performance of a chainsaw is heavily influenced by the efficiency of its engine. A well-tuned engine not only maximizes power output but also enhances cutting speed and precision. According to industry reports, chainsaws with engines that maintain a consistent RPM can improve cutting efficiency by up to 30%. This is due to the combination of optimal fuel-air mixture and appropriate chain speed, which allows for smoother cuts through various types of wood.

When considering chainsaw engine performance, two critical aspects come into play: engine size and technology. Larger engines typically provide greater torque, essential for cutting through denser materials. Additionally, modern engines increasingly incorporate advanced features such as electronic fuel injection, which adjusts the fuel mixture dynamically, leading to better fuel efficiency and reduced emissions. A study from a leading forestry resource suggests that chainsaws equipped with such technology can deliver a 25% improvement in fuel efficiency, resulting in longer operational times and less frequent refueling.

Tip: Regular maintenance of the engine can significantly enhance chainsaw performance. Ensure that air filters are cleaned and spark plugs are replaced as needed. This not only helps in maintaining optimal RPM but also extends the overall lifespan of the chainsaw.

Understanding the relationship between the engine and its cutting efficiency is vital for anyone looking to optimize their chainsaw’s performance. By investing time in engine maintenance and selecting the right engine specifications for your cutting needs, you can experience smoother and more efficient cutting operations while also minimizing downtime.

Tip: Always refer to the manufacturer's guidelines for engine tuning and maintenance to ensure that you are achieving the best performance without compromising safety.

The Role of the Chain in Achieving Optimal Cutting Speed

The chain of a chainsaw is a critical component that plays a pivotal role in determining cutting speed and efficiency. A well-maintained chain ensures that your chainsaw operates at its optimal performance level. The sharpness of the teeth and the tension of the chain directly influence how smoothly it cuts through wood. Dull teeth not only slow down your work but can also put undue stress on the motor, leading to potential damage and increased wear over time.

Tips: Regularly inspect the chain for wear and tear, and make it a habit to sharpen the teeth after extended use. This can significantly improve your cutting speed and effectiveness. Additionally, maintaining the proper tension of the chain is essential; an appropriately tensioned chain reduces the risk of kickback and allows for a safer cutting experience.

Furthermore, the type of chain you use can also affect performance. Different cutting tasks may require specific chain designs—such as skip tooth or full complement chains—each tailored for varying cutting conditions. Evaluating the type of wood and the intended cuts can guide you in selecting the right chain for the job.

Tips: When switching chains, take a moment to research the specifications suited for your project. It may also be beneficial to keep a spare chain on hand, so you can quickly change out and keep working without losing momentum.

Maintaining Your Chainsaw: A Guide to Essential Spare Parts

Maintaining your chainsaw is crucial for its optimal performance and longevity. Understanding the essential spare parts your chainsaw needs will help you avoid breakdowns and keep your equipment in top shape. Key components such as the chain, bar, air filter, spark plug, and fuel filter play significant roles in ensuring that your chainsaw runs smoothly and efficiently. Regularly checking and replacing these parts will not only enhance performance but also improve safety during operation.

Tips for maintaining your chainsaw include regularly sharpening the chain to reduce wear and tear, ensuring that the bar is lubricated consistently, and cleaning or replacing the air filter to prevent engine strain. It's also advisable to check the spark plug for wear, as a faulty spark plug can lead to starting issues. Additionally, store your chainsaw in a dry and secure place to protect it from environmental elements that could damage its components.

Investing time in maintaining these essential parts will pay off by extending the life of your chainsaw and improving its cutting efficiency. Make it a habit to perform routine inspections and keep a checklist of spare parts to monitor their condition actively. This proactive approach will ensure you’re always ready for your next project.

Related Posts

-

Essential Chainsaw Parts You Didn't Know You Needed: Maximize Performance and Safety

-

Brush Cutter Challenges You Should Know Before Buying

-

Innovative Gasoline Engine Parts Showcased at the 138th China Import and Export Fair in 2025

-

Unleashing Power: How to Choose the Perfect Stihl Chainsaw for Your Projects

-

Top 5 Gasoline Chain Saws for Effortless Outdoor Chores You Need to Know

-

Top 10 China Chain Saw Models You Should Consider Buying