How to Choose the Right Sprayer Parts for Your Equipment?

Choosing the right sprayer parts is crucial for optimal equipment performance. According to John McAllister, a leading expert in the sprayer parts industry, “Selecting the correct components can enhance efficiency and reduce maintenance costs.” This insight emphasizes the importance of informed decisions when it comes to sprayer parts.

Many factors need consideration. Compatibility with existing equipment is vital. Poor choices can lead to inefficiencies. Additionally, quality should not be overlooked. Low-quality parts may save money initially but can result in larger expenses over time. It's all about balancing cost and quality effectively.

There are numerous options in the market. With so many choices, it's easy to feel overwhelmed. The right part should ensure reliability and longevity. Reflecting on personal experiences can guide better decisions in the future. Finding that balance is often a challenge, yet essential for achieving satisfactory results in all spraying applications.

Understanding Different Types of Sprayer Parts Available on the Market

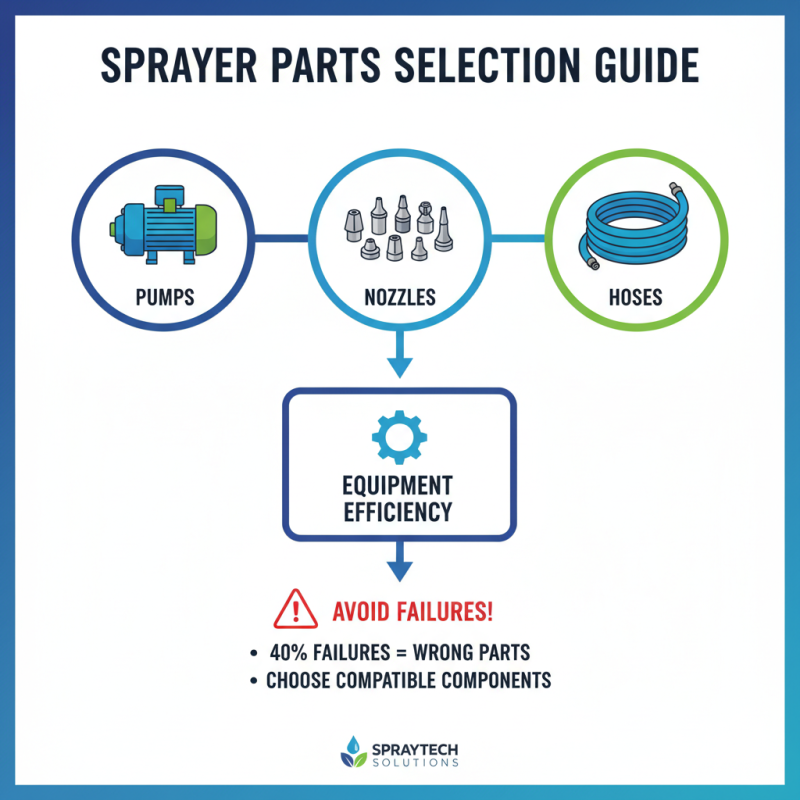

When selecting sprayer parts, understanding the available types is crucial. There are standard components like pumps, nozzles, and hoses. Each plays a vital role in the overall efficiency of your equipment. According to a recent industry report, up to 40% of sprayer failures can be traced back to improper parts selection. This highlights the importance of choosing compatible components.

Pumps are essential as they determine the flow rate. Choosing the right pump affects not only efficiency but also the durability of the equipment. Know that not every pump suits every task. Hoses vary in pressure ratings and materials, which influence their lifespan and performance under different conditions. In fact, nearly 30% of equipment issues come from using subpar hoses.

Nozzles also require careful consideration. Variability in spray patterns can greatly affect coverage. A poor nozzle choice can lead to uneven application and waste. According to research, improper nozzle selection results in a 20% increase in chemical usage. Rethink your component choices carefully. Aim for a balance between functionality and cost.

Assessing Compatibility with Your Specific Sprayer Model and Brand

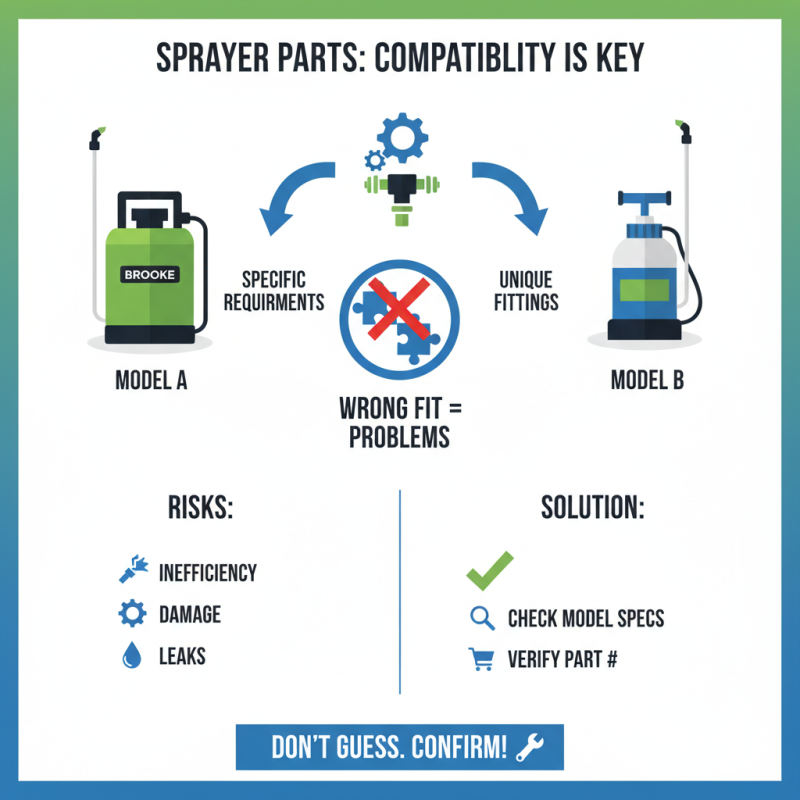

When selecting sprayer parts, compatibility with your sprayer model is crucial. Different models have specific requirements. A part that looks similar may not fit correctly. This can lead to inefficiency or damage. Check the specifications of your sprayer before purchasing. This step is often overlooked but essential.

Always refer to your equipment's manual. It provides key information about compatible parts. Sometimes, the correct size or type is not intuitive. It can be frustrating to deal with returns or exchanges. Consider consulting with experts if unsure. They can offer guidance based on experience.

However, don’t rely solely on advice; do your own research. Online resources can help clarify which parts work best. Product reviews can offer insights into performance. Take the time to compare options. A hastily made decision might lead you to regret later. The right parts ensure your equipment runs smoothly and efficiently.

Essential Features to Consider When Selecting Sprayer Components

When selecting sprayer components, it's essential to understand key features that affect performance and efficiency. The nozzle size is crucial. A nozzle that is too large can lead to wastage of material, while one that is too small may not provide adequate coverage. According to industry reports, nearly 30% of spraying inefficiency stems from improper nozzle selection.

Another important aspect is the material of the sprayer parts. Components made from high-grade materials tend to last longer and withstand harsh chemicals. A survey indicated that sprayer maintenance costs can be reduced by 25% when using durable materials. Users often overlook this, opting for cheaper parts, which can lead to frequent replacements and increased downtime.

Compatibility with existing equipment is also vital. Mismatched parts can lead to poor performance and even equipment failure. It's common to see sprayers underperform simply due to the wrong parts being installed. Regular assessments of equipment and components can help prevent these costly mistakes. Taking time to reflect on these aspects can enhance the overall efficiency of your sprayer setup.

How to Choose the Right Sprayer Parts for Your Equipment? - Essential Features to Consider When Selecting Sprayer Components

| Feature | Description | Importance |

|---|---|---|

| Material | Quality of materials used in sprayer parts can affect durability and resistance to chemicals. | High |

| Compatibility | Ensure parts are compatible with your existing sprayer equipment model. | Essential |

| Ease of Installation | Consider how easy the parts are to install and replace. | Moderate |

| Performance | Look for parts known to enhance the performance of spray equipment (e.g., nozzles). | High |

| Maintenance Requirements | Assess how much maintenance each part requires over time. | Important |

| Cost | Consider the cost in relation to the value and longevity of the part. | High |

Comparing Quality and Price: Finding Value in Sprayer Parts

When choosing sprayer parts, the balance between quality and price is crucial. High-quality parts may seem expensive, but they often last longer. This translates into cost savings over time. Sometimes, opting for cheaper options feels wise, but these can wear out quickly. It’s important to weigh these factors carefully.

A thorough comparison can help uncover the best value. Look for materials that resist wear and tear. Check for compatibility with existing equipment. Not all parts labeled as "budget-friendly" deliver quality. You might spend more later if you need frequent replacements. Research customer reviews. They can provide insights into real-world performance.

What about warranties? Some parts come with better guarantees. This could indicate higher confidence in the product's durability. It's wise to consider the long-term implications. Some buyers rush decisions and later regret their choices. Taking time to evaluate options can yield better outcomes.

Maintenance Tips for Extending the Life of Your Sprayer Parts

To ensure the longevity of your sprayer parts, regular maintenance is crucial. A well-maintained sprayer can last significantly longer than one that is neglected. According to industry reports, routine checks can extend equipment life by up to 40%. Simple tasks, like cleaning the nozzle and inspecting seals, can prevent costly repairs. The right cleaning agents matter; using harsh chemicals can damage components.

Keep an eye on wear indicators. Many sprayer parts do show signs when they need attention. For example, a worn-out nozzle can lead to uneven spray patterns. This affects performance and reduces efficiency. Noticing these small changes early can save time and money.

Lubrication is another essential aspect of sprayer maintenance. Proper lubrication reduces friction and wear. It also enhances the overall performance of the sprayer. Reports suggest that certain parts can lose up to 30% efficiency when not properly lubricated. Check agricultural guidelines for effective lubrication practices. Ignoring these details can lead to serious issues down the line. Remember, proactive maintenance allows for better, more reliable usage of your sprayer equipment.

Sprayer Parts Maintenance Frequency

This bar chart displays the recommended maintenance frequency for various sprayer parts. Regular maintenance helps extend the life of your equipment and ensures optimal performance.

Related Posts

-

Why Understanding Sprayer Parts is Essential for Efficient Application

-

Solutions for Maximizing Efficiency with Gasoline Chain Saws in the Forestry Industry

-

How to Choose the Right Garden Tools for Your Outdoor Projects

-

Common Issues Faced with Lawn Mower Parts and How to Fix Them

-

Top 10 Reasons to Choose Stihl Chainsaws for Your Cutting Needs

-

Emerging Trends in Hand Held Chain Saws at the 2025 China Import and Export Fair with Market Growth Projections