2026 Top Sprayer Parts to Consider for Enhanced Agricultural Efficiency?

In modern agriculture, the efficiency of operations significantly relies on high-quality sprayer parts. According to the 2022 Agricultural Equipment Market Report, efficient sprayers can reduce chemical application costs by up to 30%. As farmers strive to maximize yield while minimizing waste, the role of sprayer parts becomes increasingly critical. It’s essential to note that not all parts are created equal; some may underperform or lead to equipment malfunctions.

Choosing the right sprayer parts can directly impact crop health and overall productivity. A study by Agri-Tech Insights highlights that outdated or ineffective parts can result in a 15% decline in application precision. This indicates the necessity for carefully selecting parts based on specific needs. Farmers often find themselves overwhelmed by options, which can lead to hasty decisions.

As we look towards 2026, investing in advanced sprayer components will be vital. Enhanced spray systems not only improve operational efficiency but also contribute to sustainable farming practices. However, with the rapid evolution of technology, staying informed is essential. Ultimately, ensuring you have top-notch sprayer parts is not just a choice; it's a necessity for the future of farming.

Key Components for Sprayer Efficiency in Agriculture

In modern agriculture, sprayer efficiency is crucial. Key components play a significant role. According to industry reports, up to 30% of pesticides can be wasted due to suboptimal sprayer performance. This has ecological and economic implications. Enhancing sprayer efficiency can lead to significant savings.

Nozzle design is a critical area to consider. Different nozzle types can alter droplet size and distribution. Research indicates that the right nozzle can improve coverage by 50%. This means better pest control with fewer chemicals, which is essential in sustainable farming.

Another important component is the pump system. A well-designed pump can maintain steady pressure, crucial for uniform application. Conversely, inconsistencies can lead to uneven spraying. Data shows that improving pump efficiency can reduce water use by 15% annually. These adjustments not only increase efficiency but also encourage thoughtful practices in resource management. However, many farmers overlook these key components, suggesting a significant area for improvement in agricultural methodologies.

2026 Top Sprayer Parts to Consider for Enhanced Agricultural Efficiency

| Component | Function | Benefits | Considerations |

|---|---|---|---|

| Nozzle | Distributes chemicals | Improves spray pattern and coverage | Select for droplet size and pressure |

| Pump | Generates pressure | Ensures consistent flow and application | Consider flow rate and horsepower |

| Filter | Prevents clogging | Increases system reliability | Check for easy cleaning and replacement |

| Tank | Holds spray solution | Larger capacity increases efficiency | Material should be corrosion-resistant |

| Hoses | Transports chemicals | Durability ensures long-term use | Check diameter and pressure ratings |

Criteria for Selecting High-Quality Sprayer Parts

When selecting high-quality sprayer parts, several criteria come into play. It's crucial to assess compatibility with existing equipment. An ill-suited part can lead to inefficiencies. Studies show that improper part integration can reduce sprayer efficiency by up to 25%. Look for components that meet industry standards. For instance, parts made from durable materials can withstand harsh agricultural environments, ensuring longevity.

Tips: Always check the material specifications. Parts made from corrosion-resistant metals tend to last longer. Consider modular designs. These facilitate easier replacements and upgrades.

Performance is another key factor. Components should facilitate optimal fluid distribution. Uneven application can lead to crop damage. Some reports indicate that uneven spray patterns can cut yield by 10%. It's wise to review user feedback before making a decision. Look for insights on real-world performance.

Tips: Reach out to fellow farmers or join online forums. User experiences often reveal strengths and weaknesses of various parts. This information can guide your choices. Investing time in research can lead to better agricultural outcomes in the long run.

Innovative Technologies in Sprayer Design for 2026

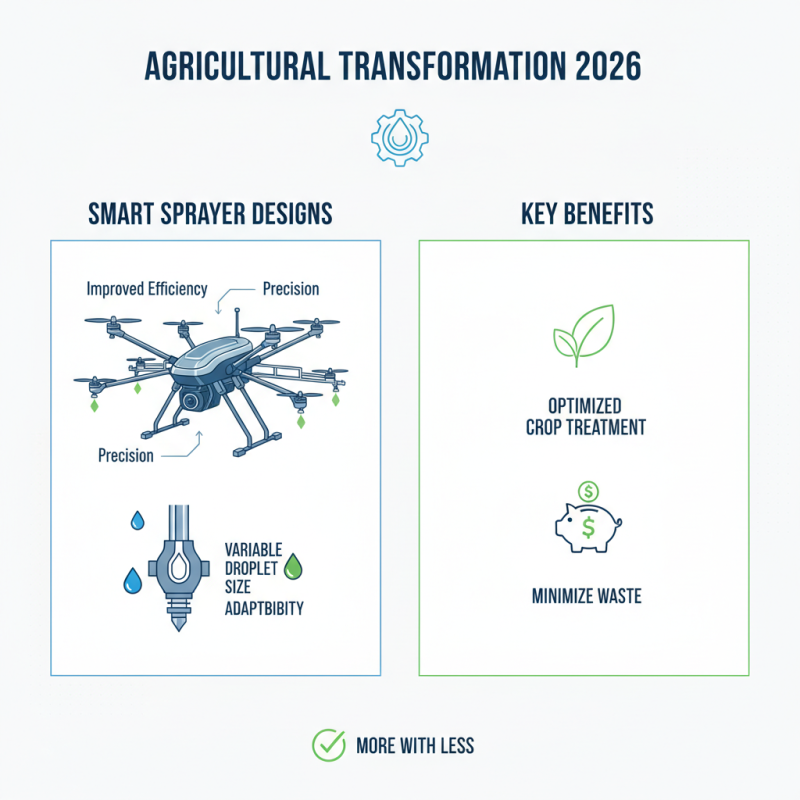

The agricultural industry is on the brink of transformation in 2026. Innovative sprayer designs focus on improved efficiency and precision. New technologies include enhanced nozzle systems that allow for variable droplet sizes. This adaptability ensures crops receive the right amount of treatment. Farmers appreciate equipment that minimizes waste, especially when resources are limited.

Automation is another key area. Sprayer drones are being developed to monitor fields in real time. These drones gather data on crop health, allowing better targeting of resources. However, the reliance on technology raises concerns about maintenance and operational expertise. Are operators trained enough to handle such advanced systems?

Another interesting aspect is user-friendly interfaces. Digital dashboards offer insights that simplify decision-making for farmers. Yet, complexity can be a double-edged sword. More features often mean a steeper learning curve. Farmers must balance embracing new tech with ensuring that it's effective. As 2026 approaches, these innovations promise a bright but challenging future in agriculture.

Maintenance Practices for Optimal Sprayer Performance

Proper maintenance of sprayers is crucial to achieving optimal performance in agriculture. Regularly inspecting parts like nozzles and filters helps prevent clogs. A clean nozzle ensures even spray patterns, which leads to better crop coverage. Over time, wear and tear can affect performance, leading to uneven application. Ignoring these signs can result in costly mistakes.

Checking fluid levels is essential for effective operation. Insufficient fluid can cause pressure drops, impacting spray efficiency. Schedule routine checks to ensure you have enough solution. It’s also important to clean the entire system after each use. This prevents residue buildup, which can hinder performance in future applications.

Consider investing time in training. Understanding how sprayers work can lead to better decision-making. Mistakes made during application may not be evident until crop damage occurs. Reflecting on past experiences can help improve practices. Share knowledge with fellow farmers. Collaborative discussions often lead to insights that enhance efficiency.

2026 Top Sprayer Parts for Enhanced Agricultural Efficiency

Future Trends in Agricultural Sprayer Parts Development

The agricultural sprayer industry is evolving rapidly. Recent reports indicate a shift towards precision application technologies. Farmers now seek parts that enhance efficiency while reducing waste. In fact, the market for precision sprayers is projected to grow by 15% annually, reflecting a strong demand.

One emerging trend is the use of smart sprayer systems. These systems integrate sensors for real-time monitoring. They adjust spray rates based on crop needs. The goal is to minimize chemical use, which is becoming increasingly important. However, not all farmers are ready for this change. Some lack the knowledge or financial resources to adopt these new technologies.

Another area of focus is durability. Sprayer parts must endure harsh conditions. Corrosion resistance and wear life are critical considerations. Recent studies emphasize that high-quality materials significantly extend lifespan. Yet, some manufacturers still cut corners, leading to frequent breakdowns. This inconsistency raises questions about long-term costs and benefits. Overall, while innovations promise enhanced agricultural efficiency, the industry must address these challenges to achieve widespread adoption.

Related Posts

-

Why Understanding Sprayer Parts is Essential for Efficient Application

-

How to Choose the Right Sprayer Parts for Your Equipment?

-

How to Choose the Best Chain Saw 40.2cc for Your Needs in 2025

-

How to Choose the Best Chainsaw for Your Needs in 2025

-

Why Hand Held Chain Saws Are Revolutionizing Outdoor Cutting Tasks

-

7 Essential Garden Tools Tips for Thriving Home Gardens